Take full control of your reverse osmosis system

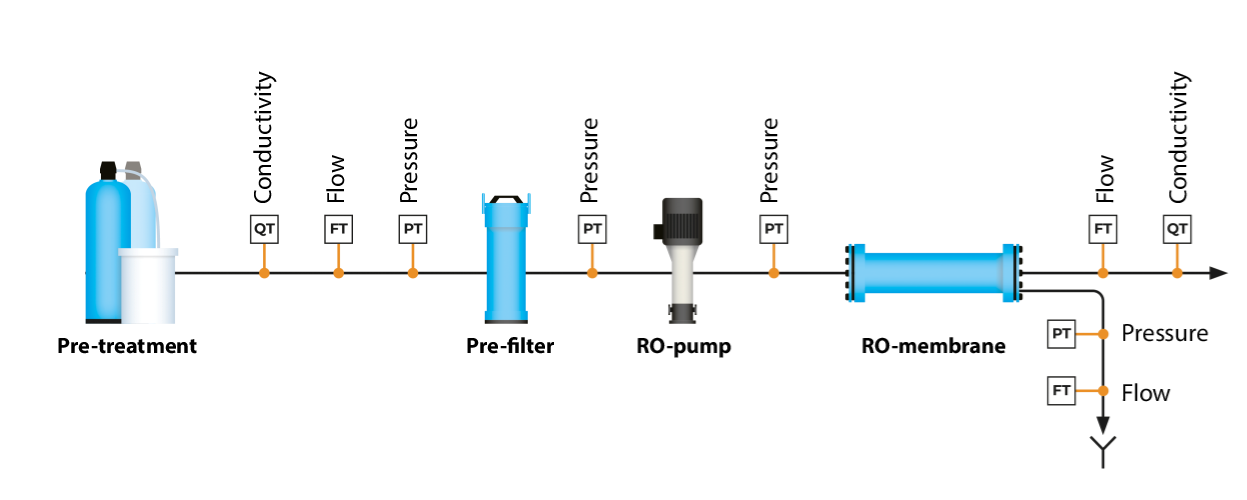

Efficient control system is the key to a successful long-term and trouble-free operation. In operating a safe and reliable reverse osmosis process, various important parameters must be controlled. With monitoring of pressure, flow, and conductivity, the SE40 control panel from EUROWATER provides full control of your RO system including pre-treatment consisting of softening or antiscalant dosing.

SE40 is designed and developed by EUROWATER's own programmers. This is your guarantee of flexible software that can be configured to your needs. At the same time, we can provide qualified and prompt support in the event of unforeseen events.

Why choose a SE40 control

Performance measurements

The SE40 can be used for monitoring pressure, flow, and conductivity. It gives a comprehensive overview of the state of the RO unit, as well as a valuable insight into the supply of the right water quality.

- PT - Pressure transmitter

The condition of the RO membrane(s) as well as the pre-filter indicated by differential pressure measurements. - FT - Flow transmitter

RO performance based on flow measurements. - QT - Quality transmitter

Water quality measurements on inlet can reveal important variations in operating conditions.

SE40 features

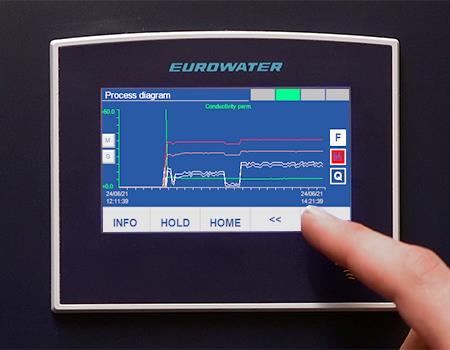

Through the touch screen you have access to a wide range of operating data that helps you optimize operating conditions and maintenance.

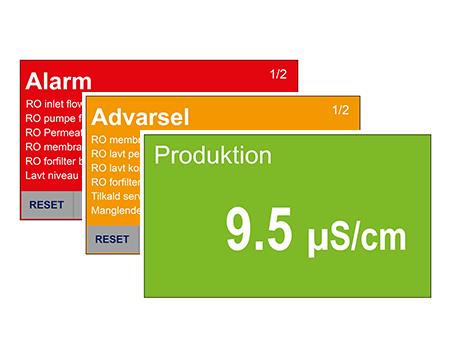

Straightforward information

Self-explanatory graphical user-interface (GUI). Color indication status during production, stand-by, warning, alarm.

Digital logbook

Operating data is stored locally and events are recorded automatically. Manual entry of logbook events is possible.

Visualized operating data

Selected process parameters are collected in real time. A trend analytic tool offers visuals and graphs about the operation.

Let's sum it up

One-pager with the most important information and features of the SE40 control for reverse osmosis systems.

How can we help?

If you want to know more about the SE40 control or our solutions within reverse osmosis systems, our specialists in membrane filtration are ready to help you.